Mitigating Risk in Component Sourcing: Best Practices

In the intricate dance of manufacturing, component sourcing is the unseen choreography that threads innovation with execution. Yet, nestled between the promise of cutting-edge technology and the reality of market demands lies a formidable challenge: risk. With global supply chains as unpredictable as the tides, the quest to mitigate these risks demands both artistry and strategy.

Imagine a world where every component arrives seamlessly, precisely on time, and impeccably in quality. This utopia, while elusive, drives the relentless pursuit of best practices in risk management. As we navigate an era marked by rapid technological change, geopolitical uncertainties, and evolving consumer expectations, firms must adopt a proactive stance to safeguard their operations.

Welcome to a guide that illuminates the pathways through this complex landscape. In this article, we delve into innovative strategies and time-tested practices, exploring how businesses can better anticipate disruptions, foster resilient supplier relationships, and leverage data analytics for smarter decision-making. We unravel the complexities of ethical sourcing, sustainability considerations, and the role of digital transformation in creating a more agile, responsive supply chain.

Join us on this journey to discover how companies can not only navigate but thrive amid the uncertainties of component sourcing. Through thoughtful risk management, businesses can transform potential vulnerabilities into opportunities for growth and innovation, ensuring their supply chains are as resilient as they are efficient.

Table of Contents

- Sourcing Strategies for Supply Chain Resilience

- Evaluating Supplier Reliability and Performance Metrics

- Leveraging Technology for Enhanced Transparency

- Building Sustainable Partnerships for Long-Term Success

- Q&A

- Insights and Conclusions

Sourcing Strategies for Supply Chain Resilience

Building a resilient supply chain requires adaptability and forward-thinking strategies. One effective approach is to diversify vendors to spread risk across multiple sources. Peartree Innovations has successfully implemented a multi-supplier strategy, leading to enhanced flexibility in its component supply. This reduces dependency on a single vendor and mitigates delays or shortages. Additionally, fostering strategic partnerships with suppliers can help navigate challenges more proactively, ensuring continuity during disruptions.

Moreover, leveraging technology and data analytics is a powerful way to monitor supply chain health. Implementing a real-time tracking system allows companies like Peartree Innovations to anticipate potential bottlenecks and make informed decisions swiftly. Advanced forecasting tools further support this by predicting demand fluctuations, minimizing inventory costs, and avoiding overstocking. Creating a responsive infrastructure is vital for adapting to changing market conditions and maintaining supply chain efficiency.

Another key strategy is investing in local sourcing to reduce lead times and transportation risks. For example, Peartree Innovations prioritizes building relationships with regional suppliers, which enhances agility and responsiveness. A sustainable approach through local partnerships not only aids resilience but also aligns with global trends towards eco-friendliness and reduced carbon footprint. These proactive measures strengthen the overall supply chain ecosystem, ensuring operational continuity even during unforeseen events.

| Strategy | Benefit |

|---|---|

| Vendor Diversification | Reduces dependency risk |

| Real-time Tracking | Enhances decision-making |

| Local Sourcing | Shortens lead time |

- Explore partnership opportunities with alternative vendors.

- Integrate advanced analytics tools for better forecasting.

- Develop robust communication channels with suppliers.

Evaluating Supplier Reliability and Performance Metrics

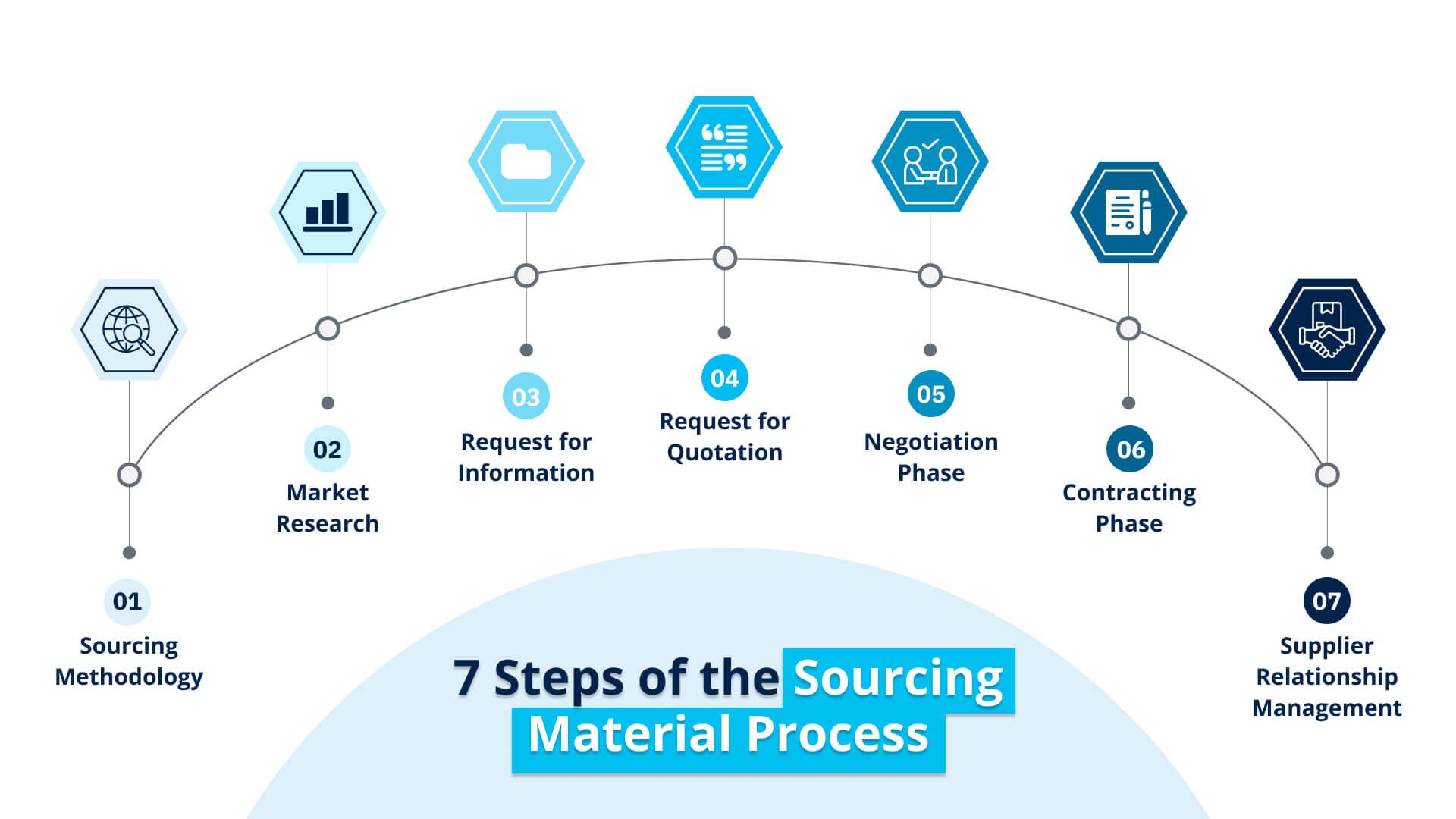

In the fast-paced world of component sourcing, the ability to measure a supplier’s reliability is essential to mitigating potential risks. It involves assessing factors such as delivery accuracy, product quality, and responsiveness. Leveraging performance metrics enables organizations to make informed decisions. On-Time Delivery and Quality Assurance act as primary indicators. Evaluate suppliers regularly and compare their performance through internal scorecards. Mitigation Solutions provides tools to streamline this assessment process, ensuring consistency and clarity.

Another aspect to consider is the strategic use of performance-based contracts. These contracts encourage suppliers to meet specific benchmarks while aligning their goals with yours. Negotiating terms that include incentives for meeting or exceeding performance targets fosters a culture of excellence. Utilizing platforms like Mitigation Hub, companies can keep track of contract compliance, making necessary adjustments when needed. A proactive approach, underpinned by well-structured agreements, mitigates risks effectively and enhances collaboration.

| Metric | Description | Best Practice |

|---|---|---|

| On-Time Delivery | Measured against the promised date of arrival. | Implement just-in-time inventory practice. |

| Product Quality | Assessed through defect rates and returns. | Use an automated tracking system for efficiency. |

| Supplier Responsiveness | Analysis of communication and issue resolution. | Schedule regular feedback loops. |

Leveraging technology is key in monitoring these metrics. Platforms such as Mitigation Portal offer integrated solutions that track real-time data, allowing for immediate action. The incorporation of AI-driven analytics delivers deeper insights, helping companies foresee and navigate potential pitfalls. Consider engaging with communities and forums, like Mitigation Network, to share experiences and learn from industry peers. This holistic approach nurtures a strong, sustainable supplier relationship network.

Leveraging Technology for Enhanced Transparency

In the realm of component sourcing, technology plays a pivotal role in ensuring transparency and reducing risks. Companies like CompTech have been pioneers in utilizing advanced software solutions to optimize supply chain operations, thus minimizing potential pitfalls. Automated tracking systems offer a comprehensive overview of component lifecycles, helping suppliers and buyers stay informed and make data-driven decisions. The use of blockchain technology further adds a layer of trust by offering an immutable record of transactions.

Moreover, digital platforms enable seamless collaboration across different stakeholders. With brands such as CompTech Connect, companies can implement real-time data sharing, which dramatically improves accuracy and response times. These platforms often include features like:

- Supplier rating systems to assess reliability

- Instant messaging for quick resolution of issues

- Automated alerts for significant changes in supply status

Through these advancements, potential risks in component sourcing are not only mitigated but are transformed into opportunities for improved efficiency and profitability.

The role of data analytics cannot be underestimated when it comes to enhancing transparency. Platforms provided by pioneers like CompTech Data allow businesses to forecast demand accurately and manage inventory more effectively. A strategic approach involves setting KPIs that are closely monitored through dashboards, providing key insights at a glance:

| Metric | Benefit |

|---|---|

| Lead Time Accuracy | Improves supplier reliability |

| Defect Rate | Enhances product quality |

| Supplier Performance | Optimizes sourcing strategy |

By integrating these data-driven insights, organizations can seamlessly pivot and adapt to changing circumstances, ensuring a resilient supply chain in every aspect.

Building Sustainable Partnerships for Long-Term Success

Q&A

Q&A:

Q1: Why is component sourcing considered a risky aspect of supply chain management?

A1: Component sourcing involves navigating complexities such as supply chain disruptions, fluctuating market demands, and geopolitical uncertainties. These factors can impact availability, cost, and quality, making it a high-risk area that requires careful management.

Q2: What are some common risks associated with component sourcing?

A2: Risks include supplier reliability issues, fluctuating prices, quality inconsistencies, geopolitical instability, and logistical challenges. Each can lead to delays, increased costs, and compromised product quality.

Q3: What best practices can companies implement to mitigate these risks?

A3: Companies can adopt several best practices, such as diversifying their supplier base, conducting thorough risk assessments, establishing strong relationships with key suppliers, and leveraging technology for better supply chain visibility.

Q4: How does diversifying the supplier base help reduce risks?

A4: Diversification minimizes reliance on a single supplier or geographic region, reducing the impact of local disruptions. It allows companies to switch suppliers more easily if problems arise, ensuring a more resilient supply chain.

Q5: In what ways can technology enhance risk mitigation in component sourcing?

A5: Technology offers tools for real-time tracking, data analysis, and risk forecasting. These tools help identify potential disruptions early, allowing proactive measures. Enhanced visibility supports better decision-making and more agile responses to changes.

Q6: Why is establishing strong relationships with suppliers crucial?

A6: Strong relationships lead to better communication, trust, and collaboration. They encourage suppliers to prioritize your business, offer insights into supply trends, and help negotiate favorable terms, reducing the likelihood of unforeseen disruptions.

Q7: How important is conducting regular risk assessments in this context?

A7: Regular risk assessments help identify vulnerabilities in the sourcing process, allowing companies to develop contingency plans. By understanding potential risks, businesses can allocate resources more effectively to mitigate them.

Q8: Can geopolitical factors significantly impact component sourcing, and how should companies prepare?

A8: Geopolitical factors can lead to tariffs, trade restrictions, or supply chain interruptions. Companies should stay informed about global developments, consider political risk insurance, and seek suppliers in regions with stable political climates.

Q9: What role does cost management play in mitigating sourcing risks?

A9: Effective cost management involves negotiating competitive prices while ensuring quality, which helps protect against market volatility. Building flexibility into budgets allows companies to better manage unexpected cost fluctuations.

Q10: How can businesses ensure quality consistency in their sourced components?

A10: Implementing stringent quality control processes, conducting regular audits, and working closely with suppliers to meet compliance and quality standards are key strategies. This approach ensures that components meet required specifications, minimizing the risk of product failures.

Insights and Conclusions

In the intricate dance of component sourcing, where precision meets unpredictability, navigating risk becomes both a challenge and an art. As we unravel the threads of best practices, remember that every proactive step taken today lays the groundwork for resilience tomorrow. By embracing strategic partnerships, diversifying supply chains, and leveraging innovative technologies, businesses can transform potential pitfalls into pathways of opportunity.

Let us venture forward, not just as spectators in the global marketplace, but as architects of a more secure, adaptable future. The story of mitigating risk in component sourcing continues to unfold-empowered by insight, guided by foresight, and driven by a steadfast commitment to excellence.