Passive Evolution: Components Shaping 2025

We’re not talking Darwinian struggle here, no survival of the fittest demanding constant adaptation. We’re entering an era of passive evolution. Think of it as the gentle drift of a perfectly balanced ship, guided not by frantic course corrections, but by subtle adjustments in the currents around it. By 2025, the landscape of technology, business, and indeed, our lives, will be sculpted as much by quietly maturing components as by disruptive innovations. These aren’t the headlines; they’re the underlying architecture. Join us as we explore the key components in this quiet revolution, examining how their steady development is shaping the world that’s just around the corner.

Table of Contents

- Why Supply Chain Resilience Starts with the Right Distributor

- How to Handle Allocation in Times of Component Shortages

- How Supreme Components Ensures Traceability in Component Sourcing

- Benefits of Working with a Franchised Distributor vs Independent Broker

- What Makes a Component Obsolete — and How to Source Replacements

- Understanding PCN (Product Change Notification) in Component Supply

- How to Identify Fake or Counterfeit Electronic Components

- The Growing Importance of Component Compliance (REACH, RoHS, IPC)

- Power Management ICs (PMICs): Market Trends and Sourcing Tips

- Top 10 Questions to Ask Your Electronics Distributor Before Ordering

- The Role of Authorised Distributors in Supporting OEM Product Development

- Understanding Minimum Order Quantities (MOQs) and MPQs in 2025

- How to Read a Component Datasheet Like a Pro

- The Impact of Tariffs and Trade Policies on Component Pricing

- How Supreme Components Supports Urgent, Time-Critical Shipments

- Key Certifications Every Electronics Distributor Should Have

- Managing Electronic Components Inventory in High-Mix Low-Volume Manufacturing

- How to Use a BOM Scrubber to Optimize Your Component Sourcing

- Spotlight on Microchip: Popular ICs and Their Use Cases

- What You Need to Know About Long Lead Time Components

- Trends in Automotive Electronics Components: EV and ADAS Focus

- Why Buying from Asia-Pacific Distributors Could Improve Lead Times

- Custom Sourcing Requests: How Supreme Components Handles Unique BOM Needs

- The Role of Distributors in Supporting EMS Companies

- How AI is Being Used to Predict Component Lifecycles and Obsolescence

- How to Choose the Right Authorized Distributor for Electronic Components

- Top 10 Hard-to-Find Electronic Components in 2025 and Where to Source Them

- Why Buying from Authorized Distributors Prevents Counterfeit Parts

- Understanding Lead Time in Electronic Component Procurement

- The Role of Distributors in the Global Semiconductor Supply Chain

- Electronic Components Obsolescence: How to Manage Supply Risks

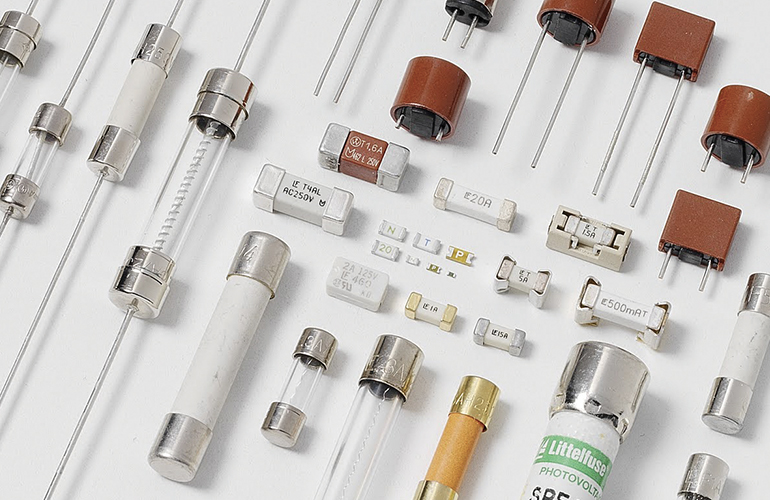

- Latest Trends in Passive Components (Capacitors, Resistors) in 2025

- Spotlight on Diodes Incorporated: Trusted Components from a Proven Manufacturer

- Why ESD Packaging Matters When Shipping Sensitive Components

- From RFQs to Delivery: How Supreme Components Streamlines Your Procurement

- ISO Certifications and Compliance: What They Mean in Component Distribution

- How AI is Revolutionizing Electronic Component Forecasting

- Understanding REACH and RoHS Compliance in Electronics Sourcing

- Global Chip Shortage Recovery: What 2025 Looks Like

- How to Evaluate a BOM for Cost-Effective Component Sourcing

- Spotlight on FPGA Sourcing: Leading Manufacturers and Stock Strategies

- The Future of MLCC Capacitors: Innovations and Shortages Explained

- Top Sourcing Challenges for Medical Device OEMs in 2025

- Authorized vs. Grey Market Electronic Components: What’s the Risk?

- The Power of Component Lifecycle Management in 2025

- Q&A

- In Summary

Why Supply Chain Resilience Starts with the Right Distributor

Imagine a complex Rube Goldberg machine, each component intricately linked, culminating in a simple task. Now, envision replacing one seemingly insignificant piece with a flawed imitation. The entire contraption sputters, grinds to a halt – a vivid analogy for today’s fragile supply chains. In the electronics industry, particularly when forecasting towards 2025 and the predicted surge in demand for passive components, this fragility is amplified. Choosing the correct distributor isn’t merely a transaction; it’s selecting the linchpin for your operational stability. It’s about mitigating risk by ensuring authenticity, traceability, and consistent availability. Don’t be tempted by superficial savings that could unravel your entire production line. The right distributor understands your needs beyond the bill of materials and acts as a strategic partner in navigating market volatility.

In the quest for robust supply chains capable of weathering global disruptions, consider these factors when evaluating a component distributor:

- Vast inventory and broad product portfolio: Offering solutions across various passive component types and manufacturers.

- End-to-end traceability: Providing verifiable documentation from origin to delivery.

- Proactive risk management: Identifying and mitigating potential supply chain disruptions before they impact your operations.

- Technical expertise: Offering knowledgeable support to assist with component selection and integration.

| Distributor Aspect | Impact on Resilience |

|---|---|

| Inventory Breadth | Reduced single-source dependency |

| Traceability | Minimizes counterfeit risk |

| Risk Management | Early warning system |

How to Handle Allocation in Times of Component Shortages

Imagine navigating a labyrinth where the path shifts with every turn, resources dwindle with each step, and the very walls seem to close in. That’s essentially what component allocation feels like during shortages. But fear not, fellow engineers and procurement specialists! Surviving this challenge hinges on proactive strategies and a healthy dose of adaptability. Think of it not as a crisis, but as an exercise in optimization and problem-solving. Diversifying your supply chain is your first line of defense. Don’t put all your eggs in one basket (or all your components in one supplier!). Explore alternative manufacturers, regional distributors, and even consider second-tier suppliers who might have availability.

Beyond diversification, consider these keys to success:

- Advanced Forecasting: Fine-tune your demand prediction using historical data and market trends.

- Early Engagement: Communicate your needs to suppliers well in advance, building strong relationships.

- Component Standardization: Reduce part variations to consolidate demand and increase sourcing flexibility.

- Design Flexibility: Explore alternative components or design modifications that allow for wider availability.

Sometimes, raw numbers tell the story best:

| Component | Lead Time (Current) | Lead Time (Pre-Shortage) | Potential Alternative |

|---|---|---|---|

| Resistor (X Series) | 52 Weeks | 12 Weeks | Resistor (Y Series) |

| Capacitor (A Type) | 40 Weeks | 8 Weeks | Capacitor (B Type) |

How Supreme Components Ensures Traceability in Component Sourcing

In the intricate dance of modern electronics, knowing where each component originates is crucial. Supreme Components tackles this challenge head-on by implementing cutting-edge traceability protocols. Like a detective meticulously piecing together a case, we track each component’s journey from the manufacturer’s floor to your doorstep. This involves:

- Rigorous Supplier Vetting: Every supplier undergoes a multi-stage approval process, ensuring compliance with quality standards and ethical practices.

- Batch-Level Tracking: Each component batch possesses a unique identifier, allowing us to monitor its movement throughout the entire supply chain.

- Comprehensive Documentation: Detailed records accompany each component, encompassing manufacturing dates, material certifications, and inspection reports.

Imagine a component’s lineage, documented like a family tree. This level of detail is achieved using blockchain technology, creating an immutable record of each component’s history. Furthermore, it’s about providing transparency and peace of mind. Here’s a simplified illustration of our traceability data:

| Component | Batch ID | Manufacturer | Date of Manufacture |

|---|---|---|---|

| Resistor (1kΩ) | R1K-2024-A01 | OhmTech Inc. | 2024-03-15 |

| Capacitor (10µF) | C10U-2024-B02 | Farad Components | 2024-04-01 |

Benefits of Working with a Franchised Distributor vs Independent Broker

Navigating the component landscape as we hurtle towards 2025 demands strategic alliances. Choosing between a franchised distributor and an independent broker is a pivotal decision, influencing everything from supply chain resilience to long-term cost efficiency. Franchised distributors offer a direct pipeline to the manufacturer, minimizing the risk of counterfeits and providing unparalleled access to technical expertise. This often translates into a higher initial investment but safeguards against the potentially devastating consequences of faulty or misrepresented components down the line. Think of it as investing in the foundation of your electronic architecture, ensuring stability and reliability for years to come.

Independent brokers, on the other hand, operate in a more fluid market, often boasting competitive pricing and the ability to source hard-to-find or obsolete components. While this agility can be invaluable for niche applications or short-term projects, it’s crucial to weigh the potential trade-offs. Due diligence and robust quality control measures are paramount when engaging with brokers. The benefit of their flexibility is a double-edged sword.

Consider these key aspects:

- Traceability: Franchised distributors provide verifiable component lineage.

- Support: Direct access to manufacturer expertise is a major benefit.

- Risk Mitigation: Minimizing exposure to counterfeit or substandard components.

- Pricing Volatility: Brokers can offer competitive pricing, but it’s often more variable.

- Component Sourcing: Brokers are a source of outdated items.

| Feature | Franchised Distributor | Independent Broker |

|---|---|---|

| Warranty | Direct Manufacturer | Limited/Variable |

| Lead Time | Predictable | Variable |

| Authenticity | Guaranteed | Requires Verification |

| Pricing Stability | High | Low |

What Makes a Component Obsolete — and How to Source Replacements

What Makes a Component Obsolete – and How to Source Replacements

Like ancient species adapting to a changing environment, electronic components evolve or fade away. Understanding the forces behind obsolescence is crucial for designing robust products with longevity. It’s rarely a sudden extinction; more often, it’s a gradual decline driven by factors impacting both demand and supply. Decreasing market demand due to newer, better-performing alternatives is a primary driver. Shifting manufacturing priorities, where manufacturers focus on higher-margin products, can also render perfectly functional components unavailable. And finally, fluctuating government policies and import/export regulations can cut off the supply.

So, what can you do when your essential link in the electronic chain disappears? Sourcing replacements is a multifaceted challenge. Begin by understanding the critical parameters of the obsolete component. Look beyond the datasheet; consider real-world operating conditions. Then explore these options:

- Direct Replacement: A component from another manufacturer with identical specifications.

- Form, Fit, Function (FFF) Equivalent: A component that may not be identical internally but performs the same function and is compatible with your design.

- Emulation: Using an FPGA or other programmable logic device to mimic the behavior of the obsolete component.

- Redesign: The most involved approach, requiring a new PCB layout and potentially impacting software and firmware.

| Replacement Strategy | Complexity | Cost | Risk |

|---|---|---|---|

| Direct Replacement | Low | Low | Low |

| FFF Equivalent | Medium | Medium | Medium |

| Emulation | High | High | Medium to High |

| Redesign | Very High | Very High | High |

Understanding PCN (Product Change Notification) in Component Supply

Navigating the ever-shifting landscape of component supply requires a keen awareness of PCNs. Think of them as crucial weather reports for your production forecast. A PCN is essentially a formal notification from a manufacturer to its customers, alerting them to modifications in a product. These changes can range from subtle tweaks in materials to complete redesigns impacting fit, form, or function. Ignoring these signals can leave you stranded with obsolete components or compatibility issues down the line. Staying informed enables proactive adaptation and minimizes potential disruptions.

Decoding a PCN involves paying close attention to several key areas:

- Date of Notification: Establishes the timeline for implementation.

- Nature of the Change: Specifically details the alteration being made (e.g., material substitution, design change).

- Affected Part Numbers: Clearly defines the components impacted.

- Reason for the Change: Provides context, which might include obsolescence of a raw material, improved performance, or cost reduction.

- Implementation Date: Indicates when the changed product will be available.

- Potential Impact: Highlights any potential effects on performance, reliability, or compatibility.

| Change Type | Potential Impact | Mitigation Strategy |

|---|---|---|

| Material Substitution | Altered thermal performance | Re-evaluate thermal design; conduct testing. |

| Package Change | Footprint incompatibility | Update PCB layout; verify fit. |

| EOL (End of Life) | Component Obsolescence | Identify and qualify replacement component; lifetime buy. |

How to Identify Fake or Counterfeit Electronic Components

In the intricate world of electronics, where innovation races ahead, a shadow lurks – the proliferation of fake or counterfeit components. These deceptive duplicates not only threaten the performance and reliability of devices but also pose significant safety risks. But how does the discerning engineer, hobbyist, or purchasing manager navigate this treacherous landscape? It begins with vigilance and a keen understanding of the telltale signs that separate a genuine component from a fraudulent imitation. Key indicators often involve scrutinizing packaging, markings, and the component’s physical appearance.

Protecting your projects and ensuring safety demands a proactive approach. Here are some strategies to spot those deceptive discrepancies:

- Visual Inspection: Look for inconsistencies in markings, such as misaligned text, incorrect fonts, or faded printing.

- Packaging Analysis: Authentic components typically come in high-quality packaging with correct labeling and sealing. Be wary of damaged, tampered, or generic packaging.

- Testing & Verification: Employ testing methods, including electrical testing, X-ray analysis, and decapsulation, to verify the component’s performance and internal structure.

- Source Verification: Purchase components from reputable, authorized distributors with established traceability systems.

To illustrate the variance, here’s a simplified comparison of authentic versus counterfeit capacitors:

| Characteristic | Authentic Capacitor | Counterfeit Capacitor |

|---|---|---|

| Markings | Laser-etched, precise, clear | Inconsistent, ink-jet printed, blurry |

| Packaging | Sealed, manufacturer-branded | Generic, damaged, missing labels |

| Performance | Meets datasheet specifications | Subpar, unstable, fails prematurely |

The Growing Importance of Component Compliance (REACH, RoHS, IPC)

Navigating the intricate landscape of component manufacturing is no longer solely about technological advancement; it’s increasingly about adhering to a complex web of regulations. As we hurtle towards 2025, the significance of component compliance, specifically concerning REACH, RoHS, and IPC standards, is amplified. Failure to meet these requirements isn’t just a technical oversight; it’s a potential roadblock to market access, a risk to brand reputation, and a liability to long-term sustainability. Consider the ripple effect:

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Impacts material composition and supply chain transparency.

- RoHS (Restriction of Hazardous Substances): Dictates allowed substances within electrical and electronic equipment for environmental safety.

- IPC Standards: Govern assembly processes, material selection and quality, ensuring reliable products.

The intensifying focus on ethical sourcing, environmental responsibility, and product longevity is forcing manufacturers to proactively prioritize compliance. A reactive approach is simply no longer sufficient. Staying ahead means investment in robust testing procedures, meticulous documentation, and comprehensive training for all personnel involved in the component lifecycle. The table below provides a simplified overview of potential consequences for non-compliance:

| Regulation | Non-Compliance Consequence |

|---|---|

| REACH | Product recall |

| RoHS | Market exclusion |

| IPC | Quality failure |

Power Management ICs (PMICs): Market Trends and Sourcing Tips

Delving into the intricate world of efficiency, Power Management ICs are experiencing a surge in demand, driven by the relentless pursuit of smaller, more power-efficient devices. We’re seeing trends pushing towards increased integration – expect to find more PMICs consolidating functions into a single chip, reducing board space and BOM complexity. Another hot area is the adoption of advanced packaging techniques, like wafer-level chip-scale packaging (WLCSP), enabling even smaller form factors and improved thermal performance. To navigate this landscape effectively, think beyond the datasheet. Consider the application’s specific power needs, the thermal environment, and the vendor’s reputation for reliability. Don’t overlook the value of comprehensive simulation tools and technical support; they can be crucial in identifying potential issues early in the design process.

Sourcing PMICs requires a strategic approach. It’s not just about finding the lowest price; it’s about securing a dependable supply of high-quality components. Take these into account:

- Authorized Distributors: Prioritize authorized distributors for genuine components and traceability.

- Long-Term Availability: Inquire about the component’s lifecycle and potential obsolescence.

- Quality Assurance: Request quality reports and certifications to ensure compliance with industry standards.

| Factor | Importance | Sourcing Tip |

|---|---|---|

| Reliability | Critical | Check MTBF data |

| Availability | High | Confirm stock levels |

| Support | Significant | Evaluate response time |

By understanding the market trends and adopting smart sourcing strategies, you can ensure your designs are powered by the most efficient and reliable PMICs available.

Top 10 Questions to Ask Your Electronics Distributor Before Ordering

The path to realizing your innovative vision in the evolving electronics landscape heavily relies on reliable passive components. But before you hit that order button, are you truly prepared? Your chosen electronics distributor is more than just a supplier; they are a gateway to quality, compliance, and potentially, the success of your product. Navigating the world of resistors, capacitors, and inductors requires strategic questioning. Don’t leave anything to chance; delve deeper than just price and delivery times. Knowing the right inquiries can save significant time, resources, and headaches down the line.

So, arm yourself with the knowledge to make informed decisions. Here’s a crucial checklist, ensuring a smooth journey from prototype to mass production:

- Provenance and Traceability: Can you provide complete traceability documentation for these components?

- Quality Assurance: What quality control processes are in place to guarantee component specifications?

- Counterfeit Mitigation: What steps do you take to prevent the distribution of counterfeit components?

- Compliance Certifications: Are these components compliant with relevant environmental regulations (RoHS, REACH)?

- Lead Times and Inventory: What are the realistic lead times, and what are your current stocking levels?

- Technical Support: Do you offer technical support to assist with component selection and integration?

- Minimum Order Quantities: What are the minimum order quantities for each component?

- Return Policy: What is your return policy in case of defective or incorrect components?

- Pricing Transparency: Are there any hidden fees or surcharges associated with the order?

- Long-Term Availability: Can you guarantee the long-term availability of these components for future orders?

Consider this scenario: You’re about to manufacture a groundbreaking wearable device that will reshape fitness tracking. The capacitors you select are critical for power management and signal integrity. A seemingly minor issue with these components could lead to product failures and damage your brand’s reputation. Let’s look at how a good distributor could provide key elements.

| Factor | Without Due Diligence | With Distributor Assurance |

|---|---|---|

| Component Failure Rate | Unpredictable, potentially high. | Significantly reduced due to QA. |

| Regulatory Risk | Unknown compliance status. | Confirmed RoHS/REACH compliance. |

| Supply Chain Security | Vulnerable to counterfeits. | Mitigated risk through traceability. |

| Product Lifespan | Potentially shortened by component issues. | Optimized for long-term reliability. |

The Role of Authorised Distributors in Supporting OEM Product Development

As 2025 approaches, Original Equipment Manufacturers (OEMs) face increasing pressure to innovate and bring new products to market faster than ever. Navigating the complex world of components – especially passive components – presents numerous challenges. This is where authorised distributors play a crucial, often underestimated, role. They act as more than just suppliers; they are strategic partners who can significantly impact the success of OEM product development.

These distributors offer a wealth of resources that streamline the product development process. Consider some of the key areas where their expertise shines:

- Technical Support: Providing expert advice on component selection, application engineering, and troubleshooting.

- Supply Chain Management: Ensuring on-time delivery, mitigating risks of obsolescence, and optimizing inventory levels.

- Value-Added Services: Offering services like component kitting, programming, and custom packaging to improve efficiency.

- Market Insights: Sharing information on emerging technologies, industry trends, and competitive landscape.

The table below showcases the impact that authorized distributors can have during the design phase:

| Distributor Service | OEM Benefit |

|---|---|

| Design Consultation | Reduced Development Time |

| Component Samples | Faster Prototyping |

| Technical Documentation | Minimized Errors |

Understanding Minimum Order Quantities (MOQs) and MPQs in 2025

In the ever-shifting landscape of electronics component procurement, Minimum Order Quantities (MOQs) and Minimum Package Quantities (MPQs) remain critical, yet increasingly nuanced, considerations. Imagine a world where hyper-personalization and rapid prototyping are the norm. How, then, do these seemingly rigid concepts adapt? The answer lies in evolving supply chain strategies, innovative partnerships, and a greater emphasis on demand forecasting accuracy. Instead of monolithic, unchanging MOQ stipulations, expect a more flexible, tiered approach. This might involve a premium for smaller order volumes offset by faster lead times or customized packaging configurations that optimize MPQs for specific project needs.

Consider this not as a constraint, but an opportunity. Forward-thinking manufacturers are already exploring solutions like:

- Shared Inventory Programs: Pooling resources between multiple customers for aggregated orders.

- Dynamic Pricing Models: Algorithmically adjusting MOQs based on real-time demand signals and component availability.

- Advanced Simulation Tools: Predicting optimal order volumes to minimize waste and maximize production efficiency.

These changes will necessitate a more collaborative dialogue between suppliers and buyers, demanding greater transparency and a willingness to creatively address challenges. The goal? A future where components move seamlessly, efficiently, and in precisely the right quantities.

| Component | Typical MOQ (2023) | Projected MOQ Trend (2025) |

|---|---|---|

| Resistors | 5,000 | Variable, based on grade |

| Capacitors | 3,000 | Downwards drift, shared lots |

| Microcontrollers | 1,000 | Tiered pricing, MOQ per spec |

How to Read a Component Datasheet Like a Pro

Imagine holding the blueprint to a universe of possibilities. That’s essentially what a component datasheet is – a detailed map to unlock the full potential of any electronic component. Stop treating it like a daunting wall of text filled with impenetrable jargon! Think of it as a treasure map, leading you to optimal circuit design, problem solving, and a deeper understanding of electronics. Master the art of deciphering these vital documents, and you’ll transform from a casual circuit builder into a veritable wizard of waveforms! Remember, it’s not just about numbers; it’s about narrative. The datasheet tells a story of the component’s capabilities, limitations and ideal operating conditions.

So, where do you even begin? First, hunt for the essentials. These are your non-negotiables – the defining characteristics that dictate whether the component is even suitable for your application. Then, move towards the nitty-gritty details that can optimize performance and prevent catastrophic failures. Let’s break it down into crucial areas to conquer:

- Absolute Maximum Ratings: These are the boundaries beyond which lies the fiery pit of component demise. Respect them!

- Electrical Characteristics: Understand the component’s behavior under various conditions. Think voltage, current, resistance, capacitance – all the fun stuff!

- Typical Performance Curves: Visualize the component’s performance across different operating parameters. These graphs are worth a thousand calculations.

- Package Information: Don’t overlook the physical dimensions and pinout. They’re critical for PCB layout and soldering success.

Consider this simplified comparison for popular resistor types:

| Resistor Type | Typical Tolerance | Power Rating |

|---|---|---|

| Carbon Film | 5% | 0.25W |

| Metal Film | 1% | 0.25W |

| Wirewound | 1-5% | 1-5W |

The Impact of Tariffs and Trade Policies on Component Pricing

Geopolitical winds are whipping up a storm in the component landscape. Shifting alliances and protectionist measures are no longer distant rumblings; they’re directly impacting the bottom line. Tariffs, quotas, and trade agreements, once abstract concepts, are now palpable forces, reshaping supply chains and dictating price volatility. Manufacturers find themselves in a high-stakes game of chess, constantly re-evaluating their sourcing strategies and pricing models to navigate this ever-changing terrain. The era of predictable component costs is fading, replaced by a reality where tariffs can instantly inflate the price of raw materials or finished goods. Adapting to this new reality is critical for success, demanding innovative solutions and a willingness to embrace flexibility.

The ripple effect extends far beyond the initial customs duty. Consider these factors:

- Increased material costs: Tariffs often directly increase the price of imported materials.

- Supply chain disruptions: Trade policies can lead to delays and bottlenecks.

- Currency fluctuations: Trade tensions often trigger currency volatility, affecting import/export costs.

- Geographic diversification costs: Sourcing from new locations adds expense and complexity.

To illustrate, consider this simplified scenario:

| Component | Origin | Tariff Impact | Price Increase (Estimate) |

|---|---|---|---|

| Resistor | Country A | 25% Tariff | 20% |

| Capacitor | Country B | 10% Tariff | 8% |

| Inductor | Country C | No Tariff | 0% |

This table simplifies the complex interplay of factors, but highlights the potential direct impact. The industry needs to proactively implement tariff mitigation strategies and to plan for potential price increases.

How Supreme Components Supports Urgent, Time-Critical Shipments

In the breakneck race to 2025, where innovation hinges on immediate access, Supreme Components positions itself as more than just a distributor; we’re the heartbeat sustaining your rapid prototyping and critical deployment timelines. Imagine a scenario where a production line grinds to a halt due to a single missing component – that’s where our expedited shipping solutions become your lifeline. Our logistics network is meticulously designed to shrink lead times, offering a symphony of services orchestrated for speed. We understand that every minute counts, and our commitment to rapid delivery directly translates into minimized downtime and accelerated product launches for our partners.

We achieve this through a multi-faceted approach, focusing on:

- Strategic Warehousing: Locations optimized for swift dispatch to key manufacturing hubs.

- Dedicated Account Managers: Personalized support to navigate urgent orders seamlessly.

- Real-Time Tracking: Unwavering visibility into your shipment’s journey, from our warehouse to your doorstep.

Consider these hypothetical, yet plausible, supply-chain emergencies:

| Scenario | Critical Component | Supreme Components’ Solution |

|---|---|---|

| Medical Device Prototype Delay | Sensor Module | Same-Day Air Freight |

| Automotive Production Halt | ECU Chip | Dedicated Courier Service |

| Aerospace System Failure | Power Resistor | 24/7 Emergency Support |

Key Certifications Every Electronics Distributor Should Have

Stepping into 2025, electronics distributors need more than just a handshake and a catalog. To navigate the complexities of modern component sourcing and distribution, specific certifications are becoming essential badges of trust and competence. These credentials aren’t merely decorative; they’re assurances of quality, traceability, and adherence to global standards. To be a successful player in the passive components evolution you need to highlight your reliability.

So, what are the crucial certifications to pursue? While the specific needs will vary based on your target market and product specialization, here are some cornerstones to consider:

- ISO 9001: Demonstrates a commitment to quality management systems, crucial for consistent and reliable product delivery.

- AS9120: Essential if you’re supplying the aerospace, aviation, and defense industries. This certification focuses on aerospace-specific requirements.

- Counterfeit Component Avoidance Training (e.g., ERAI, IDEA): Reduces the risk of counterfeit components entering the supply chain.

- ESD (Electrostatic Discharge) Control Program Certification: Protects sensitive electronic components from damage during handling and storage.

- Environmental Certifications (e.g., ISO 14001, RoHS Compliance): Show a commitment to environmentally responsible practices.

| Certification | Benefit | Key Area |

|---|---|---|

| ISO 9001 | Enhanced credibility | Quality Management |

| AS9120 | Aerospace Access | Supply Chain |

| EIA-ECA-649 | Lower Counterfeit risk | Component Authentication |

Managing Electronic Components Inventory in High-Mix Low-Volume Manufacturing

Navigating the intricate world of high-mix, low-volume (HMLV) manufacturing demands a meticulous approach to electronic component inventory management. Unlike mass production, HMLV environments grapple with a vast array of components, each playing a critical role in unique product builds. Effective management hinges on striking a delicate balance between minimizing excess stock and ensuring timely availability. This involves careful consideration of diverse factors, including demand forecasting (which, let’s be honest, can feel more like fortune-telling), component lead times, and the ever-present specter of obsolescence. Implementing robust tracking systems, combined with proactive communication with suppliers, becomes paramount to survival. Think of it as a high-stakes game of “Components Jenga” where one wrong move can bring the entire production line tumbling down.

The challenge isn’t just about warehousing; it’s about optimizing the entire lifecycle of each component. Consider these crucial elements:

- Accurate Demand Forecasting: Leveraging historical data and market insights to predict component needs.

- Strategic Supplier Relationships: Building strong partnerships to mitigate lead time uncertainties and ensure component availability.

- Real-Time Inventory Tracking: Employing technologies like RFID or barcode scanning for precise and up-to-date inventory visibility.

- Obsolescence Management: Proactively identifying and addressing obsolete components to avoid production disruptions.

- Just-in-Time Procurement: Ordering components only when needed to minimize storage costs and reduce the risk of obsolescence.

To illustrate the criticality of efficient inventory management, consider the following scenario:

| Component Category | Potential Impact of Stockout |

|---|---|

| Microcontrollers | Production Halt |

| Connectors | Delayed Shipment |

| Resistors | Compromised Quality |

Ultimately, mastering electronic component inventory in HMLV manufacturing is a continuous journey of refinement, adaptation, and strategic foresight.

How to Use a BOM Scrubber to Optimize Your Component Sourcing

Imagine your Bill of Materials (BOM) as a complex ecosystem, teeming with electronic components, each vital to your product’s survival. But within that ecosystem lurk inefficiencies – outdated part numbers, pricing discrepancies, and even phantom components sucking resources. A BOM scrubber acts as the environmental engineer, meticulously analyzing and refining the BOM to ensure a thriving and cost-effective component landscape.

Think of it as a digital treasure hunt, uncovering hidden savings and streamlining your procurement process. A powerful BOM Scrubber does much more than just clean up data; it can unlock competitive advantages. Here’s how:

- Standardization: Ensures consistent part numbers across the organization.

- Vendor Consolidation: Identifies opportunities to reduce the number of suppliers.

- Cost Optimization: Flags overpriced components and suggests alternative sources.

- Lifecycle Management: Alerts you to obsolete or end-of-life (EOL) parts, preventing production hiccups.

| BOM Challenge | BOM Scrubber Solution |

|---|---|

| Incorrect MPN | Automatic Correction |

| High Component Price | Suggests alternative suppliers |

| EOL Component | Flags obsolescence and recommends replacements |

Spotlight on Microchip: Popular ICs and Their Use Cases

The landscape of component innovation is ever-shifting, and Microchip Technology stands as a prominent figure, constantly fueling this ‘Passive Evolution’ we’re witnessing. But which of their integrated circuits (ICs) are truly shaping the future, and where will we see them embedded by 2025? Forget generalized overviews; let’s dive into the nitty-gritty of specific components and their future applications. Think beyond the datasheet and consider the potential.

Consider the power of the PIC microcontroller family or the diverse capabilities of the MCP operational amplifiers. Their reach extends far beyond hobbyist projects. Below, we will explore some examples. Microchip aims to serve several industries with a range of products, and is known for its:

- Reliability

- Availability

- Versatility

| IC Family | Specific IC | Possible 2025 Use Case |

|---|---|---|

| PIC Microcontrollers | PIC16F18855 | Smart sensor nodes in precision agriculture |

| Op Amps | MCP6001 | High-precision medical wearables |

| Memory | SST26VF064B | Over-the-air (OTA) firmware updates in IoT devices |

| Networking | ENC28J60 | Low-power industrial control systems |

What You Need to Know About Long Lead Time Components

Navigating the treacherous waters of component sourcing in today’s landscape requires more than just a sharp eye; it demands foresight. Predicting potential delays stemming from long lead time components is critical for staying ahead. Forget simply reacting to supply chain disruptions; successful product development now necessitates anticipating vulnerabilities *before* they impact your timeline. Think of it as playing chess with global logistics; every move, every component choice, needs to be calculated against possible future bottlenecks. Ignoring this reality is akin to launching a ship without a rudder – destined to drift aimlessly in a sea of unmet deadlines.

So, what contributes to these extended waits? It’s not always as simple as increased demand. A perfect storm of factors can extend even seemingly commonplace part procurement. These factors can include raw material scarcity, geopolitical instability, and even natural disasters affecting key manufacturing hubs. To better prepare your team, consider these:

- Raw Material Availability: Trace the origin of your critical materials

- Geopolitical Factors: Monitor global events impacting production regions

- Manufacturing Capacity: Assess the capacity of key suppliers

| Component | Typical Lead Time (Weeks) | Potential Delay Driver |

|---|---|---|

| Microcontroller | 20 | Wafer Shortage |

| Specialized Capacitor | 16 | Material Import Restrictions |

| High-Precision Resistor | 12 | Factory Fire |

Trends in Automotive Electronics Components: EV and ADAS Focus

The Road Ahead: Automotive Electronics Transformation

As the automotive landscape accelerates towards 2025, powered by relentless innovation in electric vehicles (EVs) and advanced driver-assistance systems (ADAS), the often-unsung heroes – passive electronic components – are undergoing a silent revolution. Forget bulky circuits; think miniaturization, enhanced performance under extreme conditions, and components specifically designed to handle the unique demands of high-voltage EV powertrains and sensor-rich ADAS ecosystems. These aren’t your grandfather’s resistors and capacitors; they’re cutting-edge solutions quietly orchestrating the future of mobility. The drive towards greater safety, efficiency, and autonomy hinges significantly on these evolutionary upgrades.

This paradigm shift is driven by several key factors:

- Increased power demands: EVs require robust components capable of withstanding high voltages and currents.

- Miniaturization pressures: Smaller, lighter components are essential for maximizing vehicle efficiency and packaging.

- Stringent reliability requirements: Automotive applications demand components with exceptional durability and longevity.

- ADAS functionality: Sensor-rich ADAS systems necessitate high-performance components for signal processing and data transmission.

| Component | 2023 Trend | 2025 Outlook |

|---|---|---|

| Capacitors | MLCC miniaturization | High-voltage, high-temp stability |

| Resistors | Precision current sensing | Enhanced surge protection |

| Inductors | Shielded, low loss | Higher efficiency, smaller size |

Why Buying from Asia-Pacific Distributors Could Improve Lead Times

Untangling the Supply Chain Knot

Ever feel like your component orders are taking a scenic route across the globe, adding weeks to your project timelines? Sourcing passive components closer to the manufacturing heartland could be the strategic shift you need. Consider this: Asia-Pacific’s dominance in electronics manufacturing translates directly into potential advantages. Imagine a world where proximity to key manufacturing hubs isn’t just a geographic detail, but a crucial element in streamlining your component acquisition processes. By tapping into regional distributors, you’re effectively cutting out layers of logistical complexity. Here’s how it breaks down:

- Minimized Transit Time: Components spend less time in transit, reducing the impact of unforeseen delays.

- Enhanced Communication: Easier communication with distributors, fostering quicker issue resolution and more responsive support.

- Strengthened Relationships: Building closer partnerships with local suppliers for long-term reliability.

A Bridge to Faster Fulfillment

Navigating the intricate web of global component procurement can be a daunting task. But, by embracing regional distribution within the Asia-Pacific region, businesses gain enhanced command of their supply chain velocity. To put it in perspective, consider the impact on prototyping. Need a quick turnaround for a critical passive component in your next design iteration? Local distributors can often deliver components far faster than suppliers reliant on intercontinental shipping. This not only accelerates your prototyping process but also offers a crucial buffer against potential component shortages. The right component, in the right place, at precisely the right time – achieving this requires a strategic approach to distribution. The advantages become clearer with a quick comparison:

| Factor | Global Distributor | Asia-Pacific Distributor |

|---|---|---|

| Shipping Time (Prototype) | 2-3 weeks | 3-5 days |

| Response Time (Support) | 24-48 hours | Same-day |

Custom Sourcing Requests: How Supreme Components Handles Unique BOM Needs

Navigating the landscape of Bill of Materials (BOM) procurement can feel like charting unknown waters, especially when standard components simply won’t cut it. In an era demanding specialized solutions for advancements in technology shaping 2025, bespoke requirements have become the norm, not the exception. Supreme Components thrives in this environment, offering a tailored approach to sourcing that transcends conventional limitations. Our ability to meet highly specific needs hinges on several key strengths:

- Global Network: Access to a vast network of manufacturers, distributors, and specialized suppliers worldwide.

- Technical Expertise: A team of engineers and sourcing specialists who understand the intricacies of component specifications.

- Rigorous Quality Control: Ensuring all sourced components meet exacting standards and performance requirements.

To illustrate our adaptability, consider a recent project involving a cutting-edge drone manufacturer. Their BOM included a highly specialized ceramic capacitor with extremely tight tolerances and unusual temperature coefficient requirements. The client needed guaranteed performance in extreme environments. Here’s how our strategic sourcing ensured success:

| Requirement | Supreme Components Solution |

|---|---|

| Unusual Temperature Coefficient | Identified a niche European manufacturer with expertise in custom ceramics. |

| Tight Tolerance (±0.1%) | Implemented rigorous testing protocols to verify compliance. |

| Extreme Environment Qualification | Collaborated with a third-party testing lab for environmental simulations. |

| On-time Delivery | Negotiated flexible lead times and logistics management to ensure timely arrival. |

The Role of Distributors in Supporting EMS Companies

Beyond simply moving components from point A to point B, distributors are evolving into strategic partners for Electronics Manufacturing Services (EMS) companies. The complexity of modern electronics, coupled with increasingly demanding supply chains, means EMS providers need more than just readily available parts. They need expertise, agility, and a deep understanding of the ever-shifting landscape of passive component technology. Distributors are stepping up to fill this void, offering a suite of services that go far beyond traditional logistical support.

This enhanced role manifests in several crucial ways:

- Design Support: Providing access to technical experts who can assist with component selection and optimization.

- Inventory Management: Implementing vendor-managed inventory (VMI) programs to ensure parts availability without tying up vital capital.

- Supply Chain Visibility: Offering real-time insights into component lead times and potential disruptions.

- Value-Added Services: Providing services like component taping and reeling, programming, and kitting to streamline production processes.

| Distributor Service | EMS Benefit |

|---|---|

| Technical Expertise | Reduced Design Cycle |

| VMI Programs | Lower Inventory Costs |

| Supply Chain Insights | Proactive Risk Mitigation |

| Kitting Services | Improved Production Efficiency |

How AI is Being Used to Predict Component Lifecycles and Obsolescence

Imagine a world where supply chain managers wield crystal balls, not to see the future, but to statistically anticipate it. That future is rapidly becoming reality thanks to the predictive powers of AI. We’re moving beyond reactive obsolescence management and into a proactive era. These algorithms sift through massive datasets, analyzing everything from market trends and manufacturer roadmaps to social media chatter and even weather patterns (yes, really!). This helps identify subtle signals pointing toward a component’s impending decline. The insight gained can then be used to better plan for inventory, component redesign, or search for replacements. The key is in moving from a reactive strategy to a preventative one and AI is capable of doing this successfully.

But how does this actually work in practice? Let’s break down some key areas where AI is making serious waves:

- Demand Forecasting: AI models analyze historical sales data, order patterns, and external factors to predict future demand for specific components.

- Trend Analysis: Identifying emerging technologies and shifts in industry standards that might render existing components obsolete.

- Supply Chain Risk Assessment: Evaluating potential disruptions in the supply chain (e.g., factory closures, raw material shortages) that could impact component availability.

- Predictive Maintenance: Predicting when components of an existing product will likely fail.

| AI Application | Typical Data Source | Benefit |

|---|---|---|

| Demand Prediction | Sales History | Optimized Inventory |

| Risk Assessment | News Feeds | Proactive Planning |

How to Choose the Right Authorized Distributor for Electronic Components

The clock is ticking, and 2025 will be here before we know it. Passive components – the silent workhorses shaping our electronic landscapes – are evolving faster than ever. But navigating this landscape requires the right gear, and in this case, that gear is your authorized distributor. Choosing the wrong one can lead to counterfeit parts, supply chain disruptions, and ultimately, a stall in your innovation engine.

So, how can you ensure you’re partnering with a powerhouse and not a paper tiger? It’s not just about price; it’s about trust, reliability, and expertise. Look beyond the flashy website and dig deeper. Consider these crucial aspects:

- Traceability: Can they provide a complete history of each component?

- Certifications: Are they certified to industry standards (e.g., ISO 9001)?

- Technical Support: Can they offer support and application assistance?

- Inventory Management: Do they have the components you need, when you need them?

To illustrate this, let’s consider a simplified comparison:

| Characteristic | Reputable Distributor | Unauthorized Source |

|---|---|---|

| Component Origin | Manufacturer Verified | Questionable/Unknown |

| Traceability | Full Documentation | Limited/None |

| Risk of Counterfeits | Minimal | High |

| Support Level | Dedicated Team | Limited/Online Only |

Top 10 Hard-to-Find Electronic Components in 2025 and Where to Source Them

The relentless march of miniaturization and the ever-increasing demand for specialized functionality are pushing some crucial electronic components towards near-mythical status. In 2025, navigating the labyrinthine world of component sourcing will require insider knowledge. Prepare to delve into the obscure, the discontinued (yet essential), and the newly invented parts that will make or break your next project. This isn’t your grandfather’s parts bin; this is about survival in a world of component scarcity.

Which components will become the unicorns of the electronics industry? Consider these potential contenders, along with the (highly speculative) best places to hunt for them:

- High-Precision Thin Film Resistors (0.001% Tolerance): Expect increased demand from high-frequency trading algorithms and quantum computing research.

- Miniature (0201 Package) High-Q Inductors: Essential for 5G mmWave applications and advanced drone technology.

- High-Temperature Solid Tantalum Capacitors (200°C+): Crucial for aerospace applications and the next generation of electric vehicle power electronics.

- Rad-Hardened Microcontrollers (Specific Obsolete Models): Ironically, these often remain essential for maintaining legacy space systems.

- Custom ASICs Designed for AI Inference at the Edge: Each one subtly different, making replacements incredibly challenging.

- High-Frequency, Low-Noise Amplifiers (LNAs) for SDR: Driven by the continued growth of software-defined radio applications.

- Niche RF Filters with Exceptional Selectivity: Required for increasingly congested spectral environment.

- Ultra-Low Power RTC Crystals with I2C Interface: Needed for IoT devices with stringent power consumption budgets.

- Specific Discrete Transistors Discontinued in the Late 80’s: Believe it or not, demand remains for vintage synth repairs.

- Rare Earth Magnet-Based Hall Effect Sensors (Custom): Optimized for unique robotic and automation application.

| Component | Primary Application (2025) | Potential Source |

|---|---|---|

| Thin Film Resistors | Quantum Computing | Specialized Suppliers |

| 0201 Inductors | 5G mmWave | Broker Networks |

| Rad-Hardened MCUs | Legacy Space Systems | Government Surplus |

| Obsolete Transistors | Vintage Synths | Online Auctions |

Why Buying from Authorized Distributors Prevents Counterfeit Parts

Navigating the ever-evolving landscape of electronic components in 2025 requires vigilance, especially regarding authenticity. Sourcing parts from unauthorized channels presents a significant risk, potentially introducing counterfeit components into your systems. These imitations, often visually similar to genuine articles, can exhibit drastically reduced performance, premature failure, and even pose safety hazards. The allure of lower prices in the gray market fades quickly when faced with the consequential costs of compromised reliability and potential system-wide failures.

The assurance of quality and traceability resides with authorized distributors. They maintain direct relationships with manufacturers, ensuring a verifiable chain of custody for every component. Benefits extend beyond mere product verification and include:

- Guaranteed Authenticity: Direct sourcing from manufacturers eliminates the risk of counterfeits.

- Full Traceability: Complete documentation verifies the component’s origin and handling.

- Manufacturer Warranty Support: Access to manufacturer warranties provides recourse in case of defects.

- Technical Expertise: Authorized distributors offer technical support and guidance.

| Feature | Authorized Distributor | Unauthorized Source |

|---|---|---|

| Authenticity | Guaranteed | Questionable |

| Warranty | Valid | Void |

| Traceability | Complete | Limited or None |

Understanding Lead Time in Electronic Component Procurement

Imagine a ripple effect. A design is finalized, production is greenlit, but a crucial passive component – perhaps a specific capacitor or resistor – remains elusive, stuck in a lead time limbo. This isn’t just a delay; it’s a domino impacting project timelines, budget allocations, and potentially, market entry. Today’s global landscape, coupled with intricate supply chains, amplifies this challenge, turning what once was a predictable delay into a volatile variable. Understanding this “wait time” is no longer a luxury; it’s a strategic imperative. Failing to proactively manage this can result in costly redesigns, production line standstills, and a lost competitive edge.

So, how do we decode this critical aspect of passive component acquisition? Consider these key factors:

- Component Complexity: Highly specialized or custom-built components naturally command longer fulfillment periods.

- Raw Material Availability: Fluctuations in the availability of key materials like tantalum or ceramics can significantly impact production schedules.

- Geopolitical Factors: Trade agreements, tariffs, and regional instabilities can create bottlenecks and disrupt supply chains.

- Supplier Capacity: The manufacturing capacity of the supplier and their existing order backlog play a crucial role.

- Logistics & Transportation: Shipping delays, customs clearance, and other logistical hurdles can add considerable time to delivery.

Staying informed on current lead times can be aided by monitoring industry reports and direct communication with component suppliers.

| Component Type | Typical “Wait Time” (Weeks) |

|---|---|

| Standard Resistors | 4-8 |

| MLCC Capacitors | 8-20+ |

| Tantalum Capacitors | 12-24+ |

| Specialized Inductors | 16-30+ |

The Role of Distributors in the Global Semiconductor Supply Chain

Within the intricate ecosystem of the semiconductor industry, distributors operate as vital arteries, channeling the flow of components from manufacturers to a diverse spectrum of end users. They’re much more than mere middlemen; they are strategic partners who provide essential services that smooth supply chain friction, especially in a landscape as dynamic as the one that shapes the future of essential components.

Here’s a glimpse at the crucial roles these entities play:

- Bridging the Gap: Connecting manufacturers with a vast and varied customer base.

- Inventory Management: Reducing lead times and mitigating supply chain disruptions through strategic stocking.

- Value-Added Services: Offering services like component programming, testing, and kitting that streamline the manufacturing process.

- Technical Support: Providing expertise and guidance to customers on part selection and integration, accelerating product development cycles.

| Distributor Benefit | Impact on 2025 |

|---|---|

| Localized Inventory | Faster prototyping, reduced delays. |

| Design Support | Accelerated innovation in niche applications. |

| Demand Aggregation | Better pricing, optimized resource allocation. |

Electronic Components Obsolescence: How to Manage Supply Risks

The relentless march of technological progress casts a long shadow on even the most fundamental building blocks of our electronic systems. While we marvel at the ingenuity driving innovation, the specter of obsolescence looms, threatening supply chains and innovation pipelines. Successfully navigating this landscape requires proactive strategies and a deep understanding of the factors at play. Imagine a scenario where a critical passive component, integral to a cutting-edge medical device headed to market in 2025, suddenly becomes unavailable. This isn’t a hypothetical; it’s a real risk demanding careful consideration. Addressing this means embracing careful planning and foresight.

Mitigating these risks involves a multi-faceted approach. Consider these key steps:

- Early Identification: Proactively monitor component lifecycles and anticipate potential disruptions.

- Strategic Partnerships: Build strong relationships with suppliers to gain early access to obsolescence notices.

- Last Time Buy (LTB): Strategically purchase remaining inventory to bridge the gap.

- Alternative Sourcing: Identify and qualify alternative components.

- Redesign: When necessary, redesign products to accommodate readily available components.

| Component | Application | Obsolescence Timeline | Mitigation Strategy |

|---|---|---|---|

| Specific Resistor | Power Supply | Q2 2025 | LTB + Alternative Qualification |

| Rare Capacitor | Audio Amplifier | Q4 2024 | Redesign |

| Obscure Inductor | RF Filter | Q1 2026 | Strategic Partnership |

Latest Trends in Passive Components (Capacitors, Resistors) in 2025

The Capacitor Frontier: Miniaturization and Material Science

The capacitor landscape is undergoing a radical transformation, driven by the insatiable demand for smaller, more efficient devices. Expect to see:

- Ultra-Miniaturization: Capacitors shrinking dramatically, enabling denser circuitry in wearables and IoT devices.

- Advanced Materials: A shift towards novel dielectrics like advanced ceramics and polymer films, boasting higher energy density and temperature stability.

- Increased Voltage Ratings for MLCCs: Multi-Layer Ceramic Capacitors (MLCCs) pushing boundaries, delivering higher voltage ratings without compromising size.

- Supercapacitors Rise: Hybrid supercapacitors blurring the lines between capacitors and batteries, offering rapid charge/discharge cycles for energy harvesting and backup power.

These advancements are crucial for applications ranging from electric vehicles to 5G infrastructure, where performance and space are premium.

Resistors Reimagined: Precision and Power Handling

While often overlooked, resistors are evolving beyond basic current limiting. Focus is shifting toward:

- High-Precision Thin Film Resistors: Demanding accuracy in sensor applications, expect ultra-low tolerances and temperature coefficients.

- Power Resistors for EVs: The electric vehicle revolution necessitates robust power resistors capable of handling high currents and voltages in braking and battery management systems.

- Smart Resistors: Integration of sensors and communication interfaces for real-time monitoring and control in industrial automation.

- Anti-Sulfuration Resistors: Combating harsh environments with specialized resistors designed for long-term reliability.

| Resistor Type | Key Improvement in 2025 | Application Example |

|---|---|---|

| Thin Film | Improved TCR | Precision sensors |

| Power | Enhanced heat dissipation | EV Inverters |

| Anti-Sulfur | Superior corrosion resistance | Outdoor industrial equipment |

Spotlight on Diodes Incorporated: Trusted Components from a Proven Manufacturer

Looking towards 2025, the subtle yet significant role of passive components continues to evolve, driving innovation across industries. Among the stalwarts powering this silent revolution, Diodes Incorporated stands out. They aren’t just supplying components; they’re crafting the building blocks for tomorrow’s technologies. Their extensive catalogue, encompassing diodes, transistors, MOSFETs, and logic devices, forms the backbone of countless electronic systems. Consider this; where would portable electronics be without efficient power management? Diodes Incorporated delivers precisely that, optimizing performance and extending battery life. These advancements in passive component technology are quietly making a world of difference.

What sets Diodes Incorporated apart isn’t simply their breadth of product offerings, but their dedication to quality and reliability. They consistently deliver components that meet and often exceed industry standards. This commitment is evident in their meticulous manufacturing processes and rigorous testing protocols. Here’s a glimpse at the impact they have:

| Application | Diodes Incorporated Solution | Benefit |

|---|---|---|

| Wearable Tech | Low Power Schottky Diodes | Extended Battery Life |

| Automotive Systems | Automotive-Grade Rectifiers | Enhanced Reliability |

| Power Supplies | High-Efficiency MOSFETs | Reduced Energy Consumption |

Diodes Incorporated’s components are more than just parts; they are the silent enablers of innovation. They are the reliable foundation upon which manufacturers build the future. Their impact will only amplify as we move towards 2025.

Why ESD Packaging Matters When Shipping Sensitive Components

Imagine sending a spacecraft component across the country with nothing but bubble wrap. Sounds risky, right? That’s essentially what happens when sensitive electronic components aren’t properly protected from electrostatic discharge (ESD) during shipping. Even invisible sparks can wreak havoc on their delicate circuits. These components, the building blocks of our ever-evolving technology (like those crucial elements shaping 2025 we’re discussing), are incredibly vulnerable. Ensuring their integrity during transit is not just best practice; it’s a cost-saving imperative that safeguards against manufacturing hiccups and premature product failure. It safeguards the very passive evolution we depend on.

Consider the following potential consequences if proper ESD precautions are ignored. Let’s break down the potential impact:

- Latent Defects: Damage that doesn’t immediately present, but weakens the component over time.

- Immediate Failure: The component simply stops functioning upon arrival or shortly after installation.

- Reduced Lifespan: The component’s expected operational life is significantly shortened. This is why high-tech industries put so much emphasis on advanced tech solutions.

| ESD Event | Potential Consequence |

|---|---|

| Walking across Carpet | Up to 35,000 Volts |

| Packaging improperly grounded | Component damage > $1M |

From RFQs to Delivery: How Supreme Components Streamlines Your Procurement

Navigating the world of passive components can feel like traversing a complex maze. Getting the right components, at the right price, and on time is critical for innovation. Supreme Components understands this challenge. That’s why we’ve built a streamlined process that transforms component procurement from a potential headache into a smooth, efficient flow. We are committed to helping you achieve component excellence.

Our approach focuses on clear communication, meticulous tracking, and proactive problem-solving. We ensure that every step of the process is clear and seamless:

- RFQs: Rapidly processed with transparent pricing and lead times.

- Order Confirmation: Detailed and accurate to avoid misunderstandings.

- Shipping & Tracking: Proactive updates on your shipment’s progress.

- Delivery: Ensuring components arrive on time and in optimal condition.

| Stage | Supreme Components Action | Expected Result |

|---|---|---|

| RFQ | Automated routing & quick quotes | Fastest response times |

| Sourcing | Global network leverage | Competitive pricing |

| Delivery | Proactive shipment monitoring | On-time arrival, every time |

ISO Certifications and Compliance: What They Mean in Component Distribution

In the intricate world of component distribution, adherence to ISO certifications isn’t merely a procedural formality; it’s a bedrock principle that ensures consistent quality, reliability, and global interoperability. Imagine a world where components, the tiny building blocks of our advanced technologies, are produced without standardized processes. Chaos would ensue! ISO standards provide a well defined framework to mitigate risks, improve efficiency, and foster customer trust. These certifications guarantee that every step, from sourcing raw materials to final delivery, is executed with precision and accountability. This is how high-quality electronic components arrive, functioning exactly as intended, ready to drive the ‘Passive Evolution’ we envision.

The implications of ISO compliance extend beyond simple product quality. It affects everything from supply chain transparency to environmental responsibility. Key areas influenced by ISO certifications in component distribution include:

- Quality Management (ISO 9001): Ensuring consistent component quality and reliability.

- Environmental Management (ISO 14001): Promoting eco-friendly practices in distribution processes.

- Information Security (ISO 27001): Protecting sensitive data throughout the supply chain.

- Counterfeit Components (AS6081): Mitigating the risk of counterfeit electronic parts entering the supply chain.

| Certification | Benefit for Customers | Impact on Distribution |

|---|---|---|

| ISO 9001 | Consistent Quality | Standardized Processes |

| ISO 14001 | Reduced Environmental Footprint | Sustainable Sourcing |

| AS6081 | Protection from Fakes | Enhanced Traceability |

How AI is Revolutionizing Electronic Component Forecasting

Imagine predicting the future, not with a crystal ball, but with algorithms. This isn’t science fiction; it’s the reality of electronic component forecasting powered by artificial intelligence. Gone are the days of relying solely on historical data and gut feelings. AI algorithms, fueled by machine learning, are now meticulously sifting through a vast ocean of information, from global economic indicators and geopolitical events to social media sentiment and even weather patterns, to provide remarkably accurate predictions. These intelligent systems are identifying subtle correlations and complex relationships that would be impossible for humans to discern. The result? Reduced risks, optimized inventory management, and a significant competitive edge for businesses navigating the ever-volatile electronics landscape. Think of it as having a hyper-intelligent supply chain forecaster constantly working behind the scenes, anticipating disruptions and opportunities with uncanny precision, allowing for optimized planning such as:

- Proactive Risk Mitigation: Identifying potential supply shortages before they impact production.

- Optimized Inventory Levels: Reducing carrying costs and minimizing the risk of obsolescence.

- Improved Pricing Strategies: Leveraging forecast accuracy to negotiate better deals with suppliers.

But the benefits extend far beyond simple cost savings. AI-driven forecasting is enabling a new era of agility and responsiveness in the electronic component industry. Consider the increased demand for specific capacitors due to the proliferation of electric vehicles. Traditional forecasting methods might struggle to accurately predict this surge, but AI can quickly adapt and refine its models based on real-time data. Furthermore, the capacity for AI to automate analyses, such as identifying the impact of raw materials scarcity on component manufacturing, means that businesses can better manage risks of price increases. This translates into faster innovation cycles, quicker time-to-market for new products, and the ability to capitalize on emerging trends with unprecedented speed. Here is an example of potential scenarios using AI:

| Scenario | Traditional Forecasting | AI-Powered Forecasting |

|---|---|---|

| Sudden increase in EV demand | Underestimated Demand | Accurate Demand Prediction |

| Raw Material Shortage (e.g., Tantalum) | Delayed Response | Proactive Inventory Management |

| Geopolitical event impacting logistics | Supply Chain Disruption | Alternative Sourcing Identification |

Understanding REACH and RoHS Compliance in Electronics Sourcing

Navigating the complex landscape of electronics sourcing requires more than just identifying the right component; it demands a deep understanding of environmental regulations designed to protect both human health and the planet. Two key directives that manufacturers and distributors must adhere to are REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances). These regulations dictate not only what materials can and cannot be used, but also how these components are tracked and managed throughout the supply chain. Ignoring these directives can lead to significant penalties, reputational damage, and ultimately, halt production.

Ensuring compliance is a multi-faceted process. It requires meticulous due diligence, robust testing protocols, and a transparent supply chain. Here’s a glimpse into some critical aspects:

- Material Composition Declaration: Request detailed information on the chemical composition of each component.

- Testing and Certification: Verify that components have undergone appropriate testing and hold valid certifications.

- Supply Chain Traceability: Implement systems to track the origin and processing of materials.

Furthermore, consider the following comparison of REACH and RoHS:

| Regulation | Scope | Objective |

|---|---|---|

| REACH | Chemical Substances | Protect human health & environment |

| RoHS | Specific Hazardous Substances in EEE | Restrict use of dangerous substances |

Global Chip Shortage Recovery: What 2025 Looks Like

Navigating the Semiconductor Landscape in 2025

The echoes of the global chip shortage continue to reverberate, but the industry isn’t standing still. By 2025, a multitude of factors will shape the recovery and future resilience of the semiconductor supply chain. Think beyond just increased production capacity; consider the evolving role of passive components and their impact on device architecture. The shift towards more efficient power management, driven by the rise of sustainable technologies, will necessitate:

- Advanced materials for capacitors and resistors

- Miniaturization of inductors for smaller, more powerful devices

- Diversification of sourcing to mitigate geopolitical risks

Furthermore, new production technologies like advanced packaging, coupled with AI-driven inventory management, are expected to prevent similar disruptions. The question isn’t simply *when* the shortage ends, but *how* a transformed ecosystem will operate. A glimpse at potential market share shifts by 2025, assuming current trend continuations, might look like:

| Component Type | Projected Growth |

|---|---|

| High-Precision Resistors | 8% |

| Miniaturized Capacitors | 12% |

| RF Inductors | 15% |

How to Evaluate a BOM for Cost-Effective Component Sourcing

The Bill of Materials (BOM) is your treasure map to cost-effective component sourcing, but only if you know how to read it. Simply listing components isn’t enough. You need to dissect it, analyze its DNA, and identify areas ripe for optimization. Think of yourself as a materials archaeologist, carefully unearthing hidden costs and uncovering opportunities for smarter procurement. Your tools? A keen eye for detail, a solid understanding of component lifecycles, and a ruthless commitment to value.

Consider these key aspects when evaluating your BOM. It’s more than just searching for the cheapest price. You need to consider the overall design implications, supply chain risks, and potential for standardization. Below we offer a list and a table to illustrate a possible strategy.

- Component Lifecycle Analysis: Are you specifying components nearing end-of-life?

- Supply Chain Redundancy: Do you have multiple qualified suppliers for critical parts?

- Volume Discounts: Can you leverage bulk purchasing to reduce per-unit costs?

- Alternative Components: Have you explored functionally equivalent, lower-cost alternatives?

| Component | Original Supplier | Alternative Supplier | Cost Saving |

|---|---|---|---|

| Resistor 1kΩ | Supplier A | Supplier B | 15% |

| Capacitor 10uF | Supplier C | Supplier D | 10% |

Spotlight on FPGA Sourcing: Leading Manufacturers and Stock Strategies

The future landscape of component procurement necessitates a sharp focus on Field-Programmable Gate Arrays (FPGAs). As complexity increases and lead times fluctuate, understanding the strengths of leading manufacturers and implementing strategic stock management becomes paramount. Navigating this terrain requires diligent partnership cultivation and a diversified approach. Consider these critical factors when evaluating potential suppliers:

- Technological Prowess: Evaluating manufacturer-specific architectures and performance benchmarks.

- Supply Chain Resilience: Assessing risk mitigation strategies and geographic diversity.

- Pricing Models: Negotiating favorable terms and exploring volume discounts.

Furthermore, an effective stock strategy hinges on anticipating demand and minimizing obsolescence. Agile planning and proactive communication with manufacturers are essential. The table below illustrates potential stock strategies based on risk tolerance, offering a glimpse into the nuances of FPGA inventory management:

| Stock Strategy | Risk Tolerance | Potential Benefit |

|---|---|---|

| Just-in-Time (JIT) | High | Reduced Holding Costs |

| Safety Stock | Medium | Buffer Against Delays |

| Speculative Stock | Low | Capitalize on Price Fluctuations |

The Future of MLCC Capacitors: Innovations and Shortages Explained

Imagine a world where your smartphone, sleeker than ever, boasts unimaginable processing power, yet its battery life rivals a classic Nokia. This isn’t science fiction; it’s the promise of advancements in Multi-Layer Ceramic Capacitors (MLCCs). But the path to this electronic Eden isn’t paved with silicon wafers alone. We’re facing a fork in the road, driven by breathtaking innovations and persistent supply chain strains. Expect to see breakthroughs in…

- Miniaturization: Ever smaller sizes for tighter spaces.

- Higher Capacitance: More juice packed into the same volume.

- Enhanced Temperature Stability: Reliable performance in extreme conditions.

- High Voltage Capacitors: Pushing performance in power electronics.

| Component | 2023 Lead Time | 2025 Forecast |

|---|---|---|

| High-Cap MLCC | 20 Weeks | 16 Weeks |

| Automotive Grade MLCC | 30 Weeks | 26 Weeks |

| Standard MLCC | 12 Weeks | 10 Weeks |

…But let’s not sugarcoat it. The hunger for MLCCs is insatiable, fueled by everything from electric vehicles to 5G infrastructure. Raw material scarcity and geopolitical instability add fuel to the fire, creating a volatile landscape. This environment demands strategic partnerships, proactive planning, and a willingness to embrace alternative component designs. The race is on to secure the building blocks of tomorrow’s technology.

Top Sourcing Challenges for Medical Device OEMs in 2025

Imagine a world where the pulse of healthcare technology beats in sync with the rhythm of efficient sourcing. But the path to 2025 isn’t paved with seamless deliveries and readily available components. It’s a landscape riddled with evolving complexities, demanding proactive strategies to navigate. For Medical Device OEMs, the future hinges on mastering these key obstacles:

- Supply Chain Volatility: Anticipate fluctuating material costs and geopolitical uncertainties impacting component availability.

- Regulatory Scrutiny: Prepare for increasingly stringent compliance requirements and documentation for medical-grade parts.

- Innovation Race: Stay ahead in a market demanding cutting-edge technology by sourcing components that enable the next generation of devices.

To illustrate the pressure of innovation, consider the evolving specifications for sensors used in remote patient monitoring. Meeting the demands for miniaturization, enhanced sensitivity, and battery life presents formidable sourcing hurdles:

| Sensor Characteristic | 2023 Requirement | Predicted 2025 Requirement |

|---|---|---|

| Size | 5mm x 5mm | 3mm x 3mm |

| Sensitivity | ± 0.5°C | ± 0.1°C |

| Battery Life | 7 days | 14 days |

Authorized vs. Grey Market Electronic Components: What’s the Risk?

In the ever-evolving landscape of electronics, where advancements become obsolete faster than you can say “Moore’s Law,” sourcing reliable components is paramount. But beneath the surface of seemingly identical parts lies a crucial distinction: the authorized channel versus the grey market. What appears to be a simple price difference can mask potential hazards that ripple through your entire product lifecycle. Think of it as navigating uncharted waters – one path illuminated by verifiable quality and manufacturer backing, the other shrouded in uncertainty, where counterfeit parts and questionable origins lurk. This dichotomy can make or break your product’s journey towards 2025 and beyond.

Let’s dive deeper into why choosing wisely matters. The authorized channel provides traceability and assurance that the components meet specific performance standards, backed by the original manufacturer. The grey market, however, operates outside this controlled ecosystem, raising serious concerns. Consider these key risks: