How to Evaluate a BOM for Cost-Effective Component Sourcing

The Bill of Materials. To some, it’s a dry, technical document detailing the DNA of a product. To others, it’s a treasure map leading to efficiency, profitability, and perhaps, even innovation. But like any map, its accuracy and interpretation are crucial. A single misstep, a misplaced decimal, or a forgotten supplier can turn that treasure hunt into a fool’s errand, bleeding you dry on overpriced components.

In today’s hyper-competitive marketplace, understanding and leveraging your BOM is no longer optional – it’s a survival skill. Simply listing parts and quantities is akin to navigating the ocean with only a compass and a tattered map. You need the full picture.

This article will guide you through the murky waters of BOM analysis, equipping you with the tools and strategies to evaluate its potential for cost-effective component sourcing. We’ll explore the key metrics, highlight common pitfalls, and reveal actionable steps to transform your BOM from a static list into a dynamic resource that fuels your bottom line. Prepare to unlock the hidden value within your BOM, transforming it from a potential cost center to a driver of significant savings. Let’s dive in.

Table of Contents

- Mastering BOM Analysis: Unveiling Hidden Costs in Component Selection

- Deconstructing Your BOM: Strategies for Economical and Efficient Component Sourcing

- Q&A

- The Conclusion

Mastering BOM Analysis: Unveiling Hidden Costs in Component Selection

Beyond the initial price tag, a component’s true cost lurks in the shadows, waiting to impact your project’s budget. Skillful Bill of Materials (BOM) analysis is the flashlight that illuminates these hidden expenses. We’re talking about more than just the distributor’s quote. It’s about a holistic view encompassing everything from potential obsolescence risks to the nuances of lead times and their ripple effects on your production schedule. A BOM scrub down is not a luxury; it’s a necessity for staying competitive and profitable.

So, how do you transform your BOM from a mere list of parts into a strategic cost-saving tool? It’s about asking the right questions and digging deeper. Consider these factors:

- Lifecycle Stage: Is the component reaching the end of its life? Replacements might require redesigns down the line.

- Availability: What’s the current lead time? Extended delays can halt production and inflate costs.

- Compliance: Does it meet all relevant environmental regulations (RoHS, REACH)? Non-compliance leads to hefty fines.

- Second Sourcing: Are there viable alternative suppliers to mitigate risks?

| Component | List Price | Hidden Cost Factor | Potential Impact |

|---|---|---|---|

| Resistor X | $0.05 | Long Lead Time | Production Delay |

| Capacitor Y | $0.10 | Singular Source | Supply Chain Risk |

Deconstructing Your BOM: Strategies for Economical and Efficient Component Sourcing

Let’s face it: a Bill of Materials (BOM) can feel like a Pandora’s Box. Overflowing with cryptic part numbers and supplier codes, it can be daunting to decipher, let alone optimize for cost. But consider it a roadmap! The key is learning how to read the map effectively, understanding the terrain (market conditions), and choosing the right vehicle (sourcing strategy) for your journey to economical component procurement. To do this, a comprehensive breakdown of the BOM itself is crucial. Are there opportunities to consolidate components? Are you leveraging volume discounts effectively? Let’s explore how to dismantle the complexities.

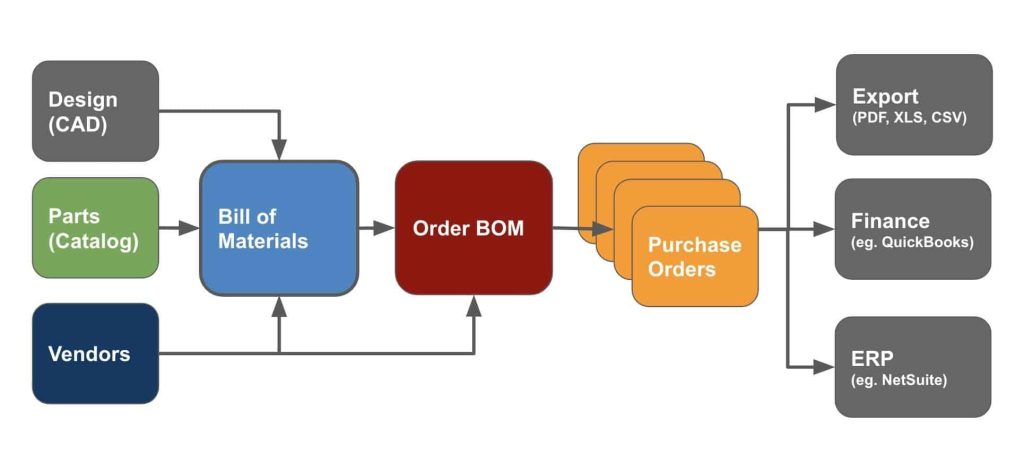

Effective component sourcing boils down to shrewd analysis and strategic execution. Think of your BOM as a living document, not a static list etched in stone. Actively manage and refine it. Here are some key tactics to consider:

- Component Standardization: Reducing the variety of components reduces complexity.

- Alternative Sourcing: Don’t be beholden to a single supplier. Explore alternatives.

- Volume Aggregation: Combine orders where possible to secure larger discounts.

- Life Cycle Management: Consider the life cycle of the parts when making sourcing decisions

Here’s a quick reference to keep in mind when evaluating:

| Evaluation Metric | Description |

|---|---|

| Unit Cost | The price per individual component. |

| Lead Time | The time required for delivery after an order is placed. |

| Minimum Order Quantity (MOQ) | The smallest quantity a supplier will sell. |

Q&A

Decoding the BOM: A Quest for Cost-Effective Components – Q&A

So, you’ve got this massive BOM staring back at you. Looks daunting. Is there even hope for finding cost savings, or are we doomed to overspending?

Q: “My BOM is a monster! Hundreds of parts, cryptic descriptions. Where do I even begin to look for cost-savings?”

A: Breathe deep, intrepid explorer! Think of your BOM as a map to a treasure trove. Start with the big rocks – the highest-value components by quantity or individual price. Applying the Pareto principle (the 80/20 rule) will likely reveal that a small percentage of components account for a large percentage of your overall cost. Focus your initial efforts there.

Q: “Okay, I’ve identified the big rocks. But what if they’re essential, top-tier components? Are cost-saving options even likely?”

A: Absolutely. Think beyond just accepting the first price you see. Consider these avenues:

Alternative Sourcing: Explore multiple suppliers for the same component. Even small price differences can add up with high volume.

Equivalent Parts: Can you substitute a functionally equivalent component from a different manufacturer? Thoroughly vet the specifications, of course!

Negotiation: Leverage your order volume to negotiate better pricing with your suppliers. Build strong relationships – long-term partnerships often yield better deals.

Q: “Substituting sounds risky. How do I ensure I’m not compromising performance or reliability by using a cheaper alternative?”

A: Caution is key! Never blindly swap parts. Rigorous testing and validation are paramount. Consider:

Datasheet Deep Dive: Scrutinize the datasheets of both the original and proposed alternatives. Compare key performance parameters, environmental ratings, and lifecycles.

Prototyping and Testing: Build prototypes with the alternative components and subject them to the same rigorous testing as your standard build.

Industry Standards: Adhere to relevant industry standards and certifications to ensure compliance and quality.

Q: “What about lead times? Sometimes chasing a cheaper part just means waiting longer and stalling production.”

A: An excellent point! Cost isn’t the only dimension. Consider the total cost of ownership, which includes:

Lead Time Impact: Calculate the financial impact of extended lead times on your production schedule and potential revenue loss.

Shipping and Handling: Factor in shipping costs, especially for international sourcing.

Inventory Management: Weigh the benefits of bulk purchases against the cost of storing excess inventory.

Q: “My BOM includes some obsolete or hard-to-find parts. Those are real cost drivers, aren’t they?”

A: Indeed. Addressing obsolescence is crucial:

Lifecycle Analysis: Regularly review your BOM to identify components nearing the end of their lifecycle.

RoHS Compliance: Ensure all components comply with Restriction of Hazardous Substances (RoHS) directives. Non-compliant parts can trigger costly rework and delays.

Authorized Distributors: Prioritize sourcing from authorized distributors to ensure component authenticity and traceability.

Q: “So, it’s not just about finding the cheapest price tag, is it?”

A: Precisely! Think of it as crafting a symphony of cost, availability, performance, and risk. A smart BOM evaluation considers the entire ecosystem of component sourcing, empowering you to create a cost-effective product without sacrificing quality or reliability. Happy hunting!

The Conclusion

So, there you have it. Evaluating your Bill of Materials for cost-effective component sourcing isn’t a one-shot deal, but rather a continuous loop of analysis, strategy, and adjustment. Think of your BOM not just as a parts list, but as a treasure map, guiding you towards optimizing costs and unlocking efficiency. Equipped with these strategies, you’re no longer just reacting to market pressures; you’re actively shaping your component landscape. Go forth and build – efficiently, effectively, and economically!